Fiber optic closures are critical components in any fiber optic network. They provide protection and organization for fiber splices and terminations at access points along the fiber cable route. Selecting the right fiber closure is important for network reliability and maintainability. This article provides an overview of fiber closure basics and considerations to help guide your closure selections.

Fiber Closure Purpose and Benefits

Fiber optic closures serve several key purposes in a fiber network:

- Protect Splices and Connectors: Closures provide a protected space for fiber splices, connectors, and slack fiber storage from outside environments and damage. Common harsh environments include underground, aerial, direct-buried, and underwater installations.

- Organization and Accessibility: Closures neatly organize internal fiber and make splice trays, connectors, and fiber slack accessible for efficient maintenance and reconfigurations via entry ports for technicians.

- Re-entry Capability: Quality closures allow simple re-entry for moves, adds, and changes without needing to disrupt other closures sites or replace entire cable lengths. Most provide resealability for 1-40+ re-entries.

Proper closure selection delivers benefits such as maximizing network reliability and longevity while minimizing installation and maintenance costs over decades of useful life.

Closure Types

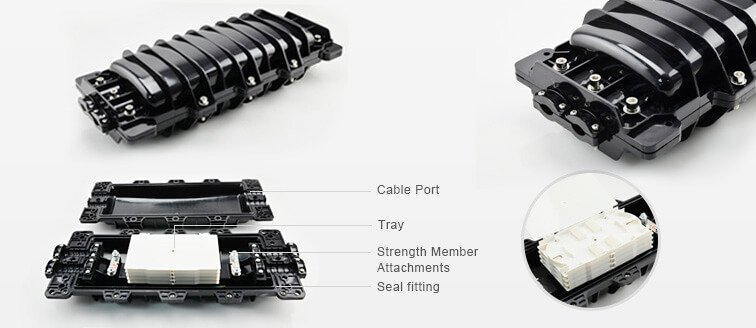

Fiber closures come in several major configurations to suit different network and environment requirements:

- Dome/Domex Closures: Round dome shape for aerial, underground, and direct-buried applications. Excellent re-entry capability and internal volume for extra slack fiber storage.

- Box/Rectangular Closures: Square/rectangular shape popular for aerial Messenger strand, pole, wall, and cabinet installations. Compact footprint.

- Below Grade Vaults: Larger heavy-duty closures for access points needing added space and protection. Used to cover street intersections and bridge crossings.

- Terminal Closures: Utilized on building entrance terminals to transition from outdoor to indoor cables. Hardened to withstand solar loads in rooftop installations.

Key Selection Considerations

Properly selecting a fiber closure depends on defining your specific network requirements and desired features. Key factors to consider include:

- Number of Cable Ports: The number of cable entry ports must suit your site’s ingress/egress needs. More ports provide serviceability for more cables as needs evolve.

- Mounting Configuration: Mounting style should suit the site such as aerial, pole, underground handhole/manhole, cabinet, etc. This impacts closure shape, splice tray orientation, and mounting accessories.

- Cable Types: Closures should match site cable jacket types (round, ribbon/harness, armored), counts, and diameters. This ensures optimal sealing, anchoring, and protection.

- Space and Growth: Understand current and future fiber counts at the site to determine internal volume and components needed. Slack fiber storage and unused capacity make networks future-proof.

- Environmental Protection: Closures rely on durable, sealed housings made of steel, hardened composites, or thermoplastics with rodent shields, moisture inhibitors, and pressure valves to defend from deployment environments.

- Re-entry: Consider how often the closure must be accessed for moves, adds, and changes to determine re-entry cycles specifications. Look for simple field installation of extra ports or splice trays too.

Additional considerations around access point locations, technician skill levels, operating temperature ratings, manufacturer quality/experience, network architecture codes/standards compliance, and project budgets factor in as well.

Leverage manufacturer and distributor expertise regarding site needs and closure specifications where helpful to find the right solution.

Summary and Next Steps

Fiber optic closures provide vital connectivity and protection at fiber cable routing access points. Considering key technical and network requirements when selecting closures ensures optimal network functionality, field serviceability, and lifecycle cost management. Additional closure customization options are also often available. Once you have defined closure needs for a site, fetch pricing and samples to evaluate product quality before purchase. Investing in the right fiber closures makes for smooth deployments and network longevity.

Leave a comment

Your email address will not be published. Required fields are marked *